thoughts

work

-- design

-- fabrication

-- dMBA

play

Click to download a full project PDF

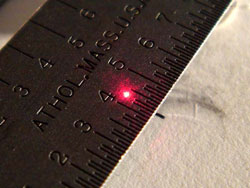

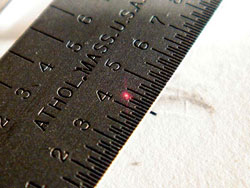

KEY INSIGHT: Laser light projected through a small hole suffers from "thin slit diffraction" which causes the beam to expand into a series of lower intensity rings. This masks the center hotspot and makes the beam appear larger than it is.

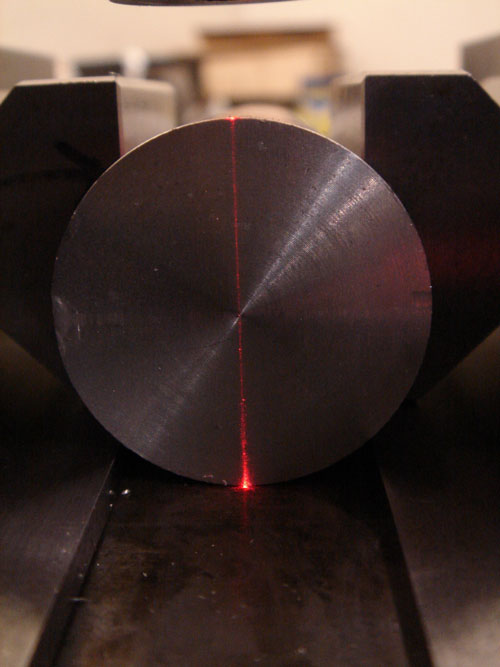

STRATEGY: Find a low cost means to effectively increase the accuracy (decrease the size) of the visible beam spot.

DESCRIPTION: After 30 years of teaching at the CSU Fresno Industrial Technology department, Dr. Skip Adrian developed a novel tool for milling machine alignment as a retirement project. Several years of development had already gone into the project when Dr. Adrian contacted me about sourcing the laser diode component from China.

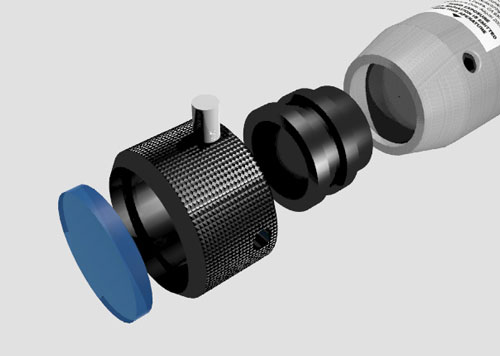

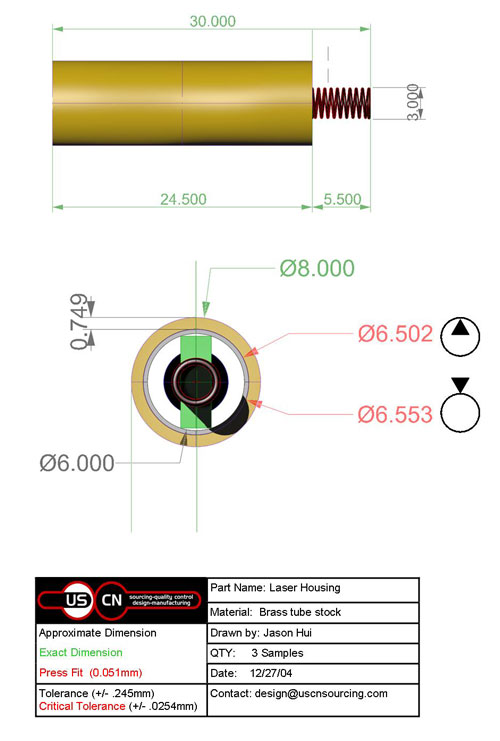

I was responsible for determining and creating technical drawings for the mechanical design of the diode module. Several weeks were spent touring factories in China and negotiating pricing. A suitable supplier was identified and I began importing laser modules and batteries for Dr. Adrian’s year old business.

After completing the above work, Dr. Adrian asked me to come up with a solution to improve the accuracy of the LC/EF.

I observed that glare from the target surface, divergence in the laser beam and thin slit diffraction through the aperture (.0035" hole) were having a negative effect on overall accuracy.

Through my experience with photography and polarized fishing glasses it occurred to me that a polarizing filter may eliminate or mitigate some of these effects. A simple test verified that a polarizer could effectively be used to adjust the observed size of the laser dot on a variety of surfaces.

OUTCOME:The polarizing attachment was initially released as an accessory item. Sales volume and customer feedback indicated that the polarizer was essential to achieving maximum accuracy and user friendliness. In August 2007 the polarizer became a standard item and is now included with every LC/EF sold. The design is also being reviewed as an additional claim to the existing utility patent on the LC/EF.

Flow Corp International, the largest manufacturer of waterjet cutting machines in the US, has signed an exclusive contract with SDA Manufacturing to distribute the LC/EF with every machine they produce.